Anodizing

According to customer needs, we can anodize the surface of aluminum products to increase the surface hardness, improve the wear resistance of products, and extend the service life of products. We can also customize different colors to meet diverse market needs.

- Sulfuric acid anodizing

- Chromic acid anodizing

- Oxalic acid anodizing

- Phosphoric acid anodizing

Electrophoresis

We can perform electrophoresis treatment on the surface of metals or alloys to form a uniform and dense protective film.

- Anodic electrophoresis

- Cathodic electrophoresis

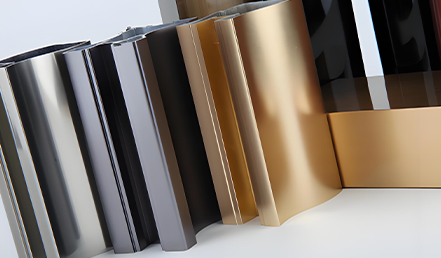

PVD vacuum coating

Under vacuum conditions, physical methods are used to vaporize the material source (such as metals, alloys or compounds) into atoms, molecules or ions, which are then transported through the gas phase and deposited on the surface of the workpiece to form a thin film with specific properties.

- Evaporation Deposition

- Sputtering Deposition

Electroplating

Electroplating is a method of depositing metal ions on the surface of an object using an electrochemical reaction. The electroplated layer has good protective and decorative properties and can improve the surface properties of the base metal, such as improving wear resistance and conductivity.

Powder coating

Powder coating is a surface coating technology that uses electrostatic spraying equipment to evenly spray powder coating on the surface of the workpiece, and then heats the coating to melt and solidify, forming a hard, wear-resistant coating. Compared with traditional liquid coating, powder coating is more environmentally friendly because it does not release organic solvents, has a higher coating utilization rate, and less waste.

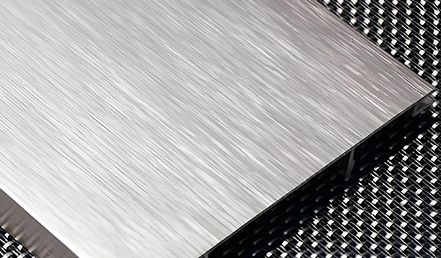

Metal brushing

Under pressure processing, fine line textures are formed on the surface of the metal through grinding consumables, which not only increases the aesthetics but also improves the anti-slip properties.

- Straight - line grained brushing

- Random - grained brushing

- Corrugated - line grained brushing

Beadblasting

Bead blasting uses compressed air as the power to spray the material (glass sand, zirconium sand, etc.) at high speed onto the surface of the workpiece to be processed. It can effectively remove surface impurities and provide a good adhesion foundation for subsequent coatings.

- Dry bead blasting

- Liquid bead blasting

- Manual bead blasting

- Automatic bead blasting

Polishing

Metal polishing is a process that uses mechanical, chemical or electrochemical methods to treat the metal surface to reduce its surface roughness and obtain a bright and smooth surface.

- Mechanical polishing

- Chemical polishing

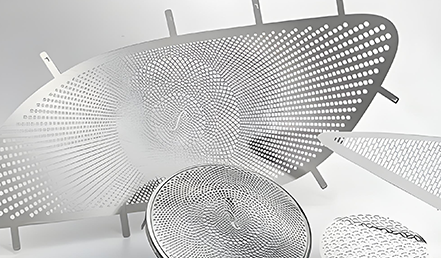

Etching

Etching is a process that selectively removes part of the material surface through chemical or physical methods to form a pattern, texture or specific shape on the material surface. It is mainly used for materials such as metals, glass, and semiconductors.

- Wet etching

- Dry etching

Laser engraving

Laser engraving is a processing technology that uses a high-energy-density laser beam to partially irradiate a material, causing physical or chemical changes on the surface of the material, thereby achieving engraved patterns and texts. The advantages are high precision and fast processing speed.

- Dot - matrix engraving

- Vector cutting

Get Quote

Get Quote

sales@crvmf.cn

sales@crvmf.cn