Automation

Automated Flexible Production Line

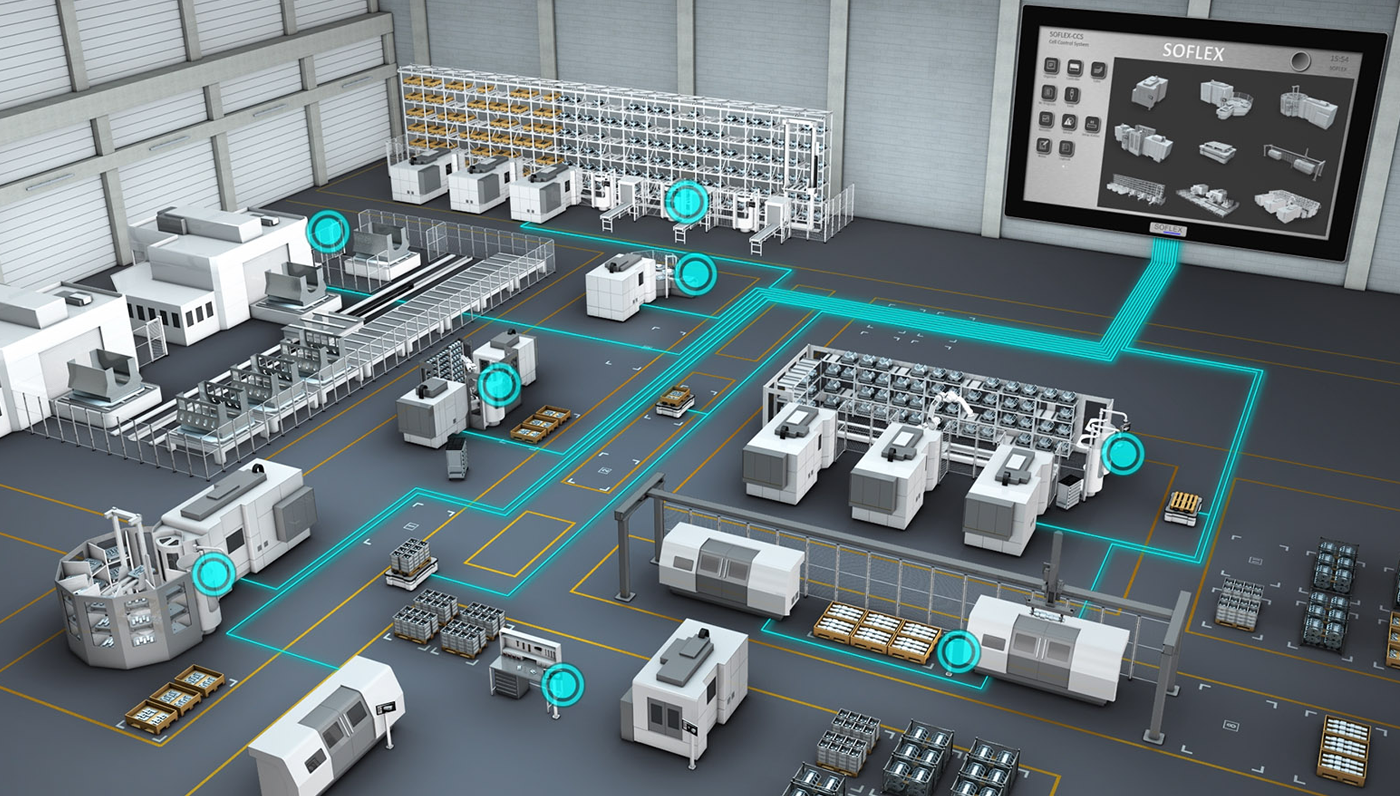

The Premier Choice for Customized Production

In today's rapidly developing manufacturing industry, enterprises have an ever-increasing demand for production efficiency, product quality, and production flexibility. To meet these diverse needs, we focus on providing the production and customization services of automated flexible production lines, helping enterprises stand out in the fierce market competition.

Our automated flexible production line integrates advanced industrial automation technology, intelligent control systems, and high-precision machinery and equipment. Through ingenious design and precise engineering implementation, a fully automated operation from raw material input to finished product output is realized. During the production process, all links work closely together. The material transfer system efficiently and accurately transports components to each processing station, and the automated processing equipment ensures that each product meets strict quality standards with its high-speed and high-precision cutting, forming, assembling, and other processes.

Our automated flexible production line has been successfully applied in many industries, achieving remarkable economic and social benefits. In the electronics manufacturing industry, the automated flexible production line customized for customers can efficiently produce various precision electronic components, such as smartphone chips and circuit boards. By realizing the automation and flexibility of the production process, the customer's production efficiency has increased by more than 40%, the product defect rate has decreased by 30%, and at the same time, it can quickly respond to changes in market demand and launch new products in a timely manner, greatly enhancing the enterprise's market competitiveness. In the automotive parts manufacturing field, our production line can accurately produce various complex automotive parts, such as engine blocks and transmission gears. With high flexibility and stability, customers can quickly switch the production of different types of parts on the same production line, reducing equipment investment and production site occupation, improving production efficiency and product quality, and providing a strong parts supply guarantee for automotive manufacturing enterprises.

Choosing our automated flexible production line and customization services means choosing an efficient, flexible, and reliable production solution. We will rely on our professional technical team, advanced technical equipment, and complete service system to create an exclusive automated flexible production line for customers, helping enterprises achieve production upgrades and sustainable development, and jointly move towards the glorious future of the manufacturing industry.

Get Quote

Get Quote

sales@crvmf.cn

sales@crvmf.cn