Manufacturing+AI

Manufacturing+AI

Leading the New Revolution in Precision Parts Machining

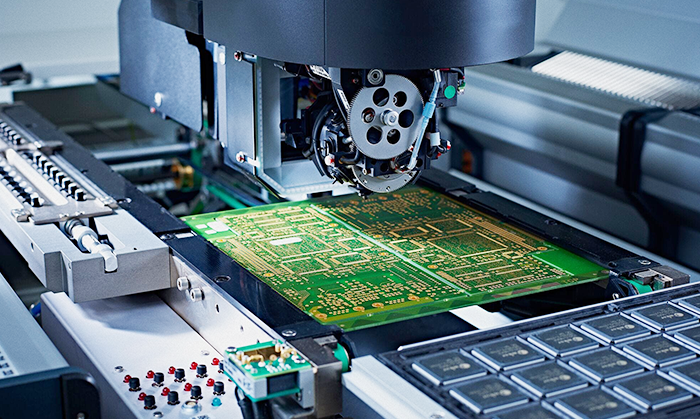

In the current digital wave of the manufacturing industry, with our profound industry accumulation and the in-depth integration of cutting-edge technology, we are fully committed to creating an innovative "Manufacturing + AI" service system, injecting new vitality into the field of precision parts machining and reshaping the industrial pattern.

On the experimental production line of core components in the automotive manufacturing industry, our service system has also achieved phased results. For the machining of transmission gears, AI monitors various data during the machining process in real-time and optimizes the machine adjustment strategies in a timely manner, making the tooth surface roughness of the gears reach an ultra-precision level, effectively reducing the transmission noise and energy consumption, and significantly enhancing the overall performance and reliability of the vehicle. It will help automotive manufacturing enterprises stand out in the fierce market competition.

In the future, our "Manufacturing + AI" service will lead the precision parts machining industry into a new era of intelligence and high efficiency with cutting-edge technology and outstanding practical achievements. Join us and embrace the brilliant future of manufacturing technology together to unlock the infinite possibilities of precision manufacturing.

Get Quote

Get Quote

sales@crvmf.cn

sales@crvmf.cn